RTL

Click to Enable

Cushion packaging serves a crucial role in logistics by acting as a protective barrier, minimizing damage risks during product transit. This packaging absorbs shocks and impacts, which are common during handling and transportation, thereby significantly reducing product damage. Research has shown that improper packaging accounts for approximately 30% of shipping damage, highlighting the importance of effective cushion packaging solutions. By selecting appropriate materials such as bubble cushion or specifically designed packing list pouches, companies can substantially decrease return rates caused by transit damages. This not only protects the cargo but also enhances customer satisfaction by ensuring the delivery of items in pristine condition.

With the rapid expansion of e-commerce, cushion packaging has become an essential component in meeting the industry's unique demands. The challenge in e-commerce lies in handling a diverse range of product sizes and shapes while maintaining safety during transit, which cushion packaging effectively addresses. High return rates, a significant concern for online retailers, can be mitigated with the use of cushioning materials, thereby ensuring fewer items return due to damages. For instance, clear packing list envelopes help optimize shipping processes while safeguarding product integrity. As online shopping continues to boom, adapting such protective techniques becomes increasingly crucial to support seamless e-commerce operations with enhanced efficiency and cost-effectiveness.

Bubble cushioning represents a popular choice for packaging due to its lightweight nature and excellent shock absorption. This material is favored by businesses for its ability to protect fragile items effectively during shipping. Meanwhile, air pillow systems offer versatility in packaging dimensions, enabling accommodation of various product sizes and reducing material wastage. Recent innovations in bubble and air pillow technologies have focused on enhancing performance while decreasing the environmental footprint—settings for these materials are becoming more efficient and eco-friendly.

Polyethylene foam is renowned for its resilience, making it ideal for safeguarding high-value items. It maintains its shape even after impacts, thus ensuring consistent protection. On the other hand, molded pulp provides an eco-friendly option, merging strength with sustainability, making it perfect for fragile products like electronics and glass items. Both materials play crucial roles in decreasing costs linked to damages by ensuring secure transport, thereby enhancing customer satisfaction and reducing return rates.

Honeycomb paper technology offers lightweight yet effective cushioning capabilities suitable for a broad spectrum of applications—from electronics to furniture. Its strength and durability make it an attractive choice for manufacturers seeking to protect products during transit. Corrugated solutions, known for their versatility, can be customized to fit specific product dimensions, further emphasizing product security. The impressive strength-to-weight ratio makes honeycomb paper and corrugated solutions popular choices among manufacturers, supporting the goal of effective cushion packaging solutions tailored for various business needs.

In the electronics sector, the fragility and high value of items like smartphones and laptops make effective cushion packaging crucial. Studies indicate that up to 15% of electronic items suffer damage during shipping, emphasizing the necessity for tailored cushion packaging solutions. Implementing proper packaging not only safeguards these devices but also enhances the unboxing experience, positively impacting customer satisfaction.

The packaging of pharmaceutical products and medical devices demands adherence to strict industry regulations, ensuring product integrity. Cushion packaging is essential in preventing breakage and contamination, preserving both functionality and safety. As the industry evolves, innovative packaging solutions are being developed to meet the unique needs of this sensitive sector, emphasizing the importance of reliable cushion packaging solutions.

Biodegradable foam alternatives provide a sustainable solution in cushion packaging while maintaining protective qualities. These eco-friendly options reduce environmental impact, unlike traditional plastic-based foams that contribute significantly to landfill waste. Research indicates that businesses integrating biodegradable materials into their packaging experience positive consumer responses, suggesting that environmentally-conscious packaging can increase brand value and consumer appeal. This shift in packaging reflects the growing demand for sustainable practices within the packaging industry and the need for brands to align with current environmental standards.

Recyclable air pillow technologies offer an efficient cushioning method while promoting sustainability in logistics. These innovative solutions not only support the reduction of waste but also contribute to circular economy initiatives by ensuring materials can be reused and recycled. Companies that adopt recyclable packaging solutions often experience enhanced brand loyalty among eco-conscious consumers. This heightened loyalty is a testament to the importance of aligning business practices with environmental goals, thereby fostering a stronger connection with consumers who prioritize sustainability.

Customized packaging plays a critical role in meeting unique product needs and stands as a core strategy in effective packaging. By tailoring packaging designs, businesses can achieve a perfect fit for their specific products, enhancing protection and minimizing damage during transit. Moreover, research shows a strong correlation between tailored packaging and increased customer satisfaction, as products arrive in pristine condition, reducing the need for returns. Ultimately, investing in bespoke cushion packaging solutions leads to significant cost savings and boosts operational efficiency, emphasizing the importance of personalized design in packaging strategies.

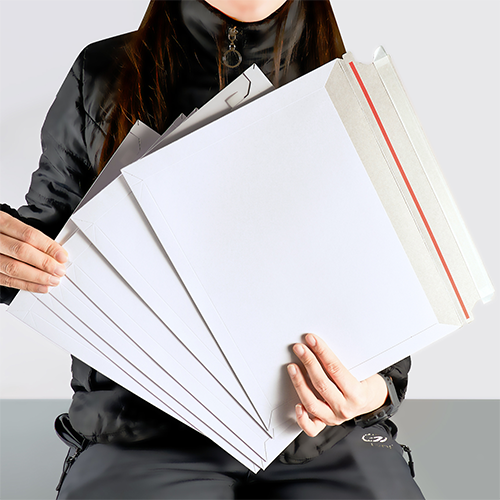

Incorporating clear packing list envelopes into logistics processes enhances delivery efficiency and sorting accuracy. These envelopes are crucial for keeping track of essential documents, minimizing the risk of mispacking or losing items—a significant factor in maintaining customer satisfaction. By providing a simple means to display packing slips and related documents, clear packing list envelopes streamline operations and help mitigate errors in shipping. This integration is especially vital in the realm of cushion packaging, where accurate handling of goods ensures every package arrives as intended, supporting streamlined logistics and improved delivery outcomes.

Investing in comprehensive staff training programs on packaging best practices is essential for elevating both the quality and consistency of cushion packaging. Properly trained personnel are more adept at ensuring packaging meets industrial standards, reducing errors that can lead to product damage and customer dissatisfaction. Implementing rigorous quality control measures is also crucial, as it guarantees that each package adheres to the established requirements, enhancing overall product experience for consumers. These initiatives not only safeguard the integrity of cushion packaging solutions but also lead to an impressive reduction in operational inefficiencies and cost overruns.