RTL

Click to Enable

Air cushion technology is a revolutionary method in cushioning fragile items for shipping. By utilizing air-filled pockets, these cushions act as a protective barrier that absorbs shock and vibrations, minimizing potential damage during transit. The lightweight nature of air cushion materials, such as inflatable padding and airbags, not only ensures effective shock absorption but also significantly reduces shipping costs by lowering the overall shipment weight. Industry statistics highlight this benefit; for instance, a study indicated a 60% reduction in damage claims when air cushions replaced traditional packaging methods. This makes air cushion technology an optimal choice for businesses aiming to enhance product protection while minimizing logistical expenses.

Foam and honeycomb structures offer robust solutions for customized shock absorption, particularly for fragile items. These structures distribute impact forces evenly, which is vital for preserving the integrity of delicate products during transit. Foam packaging, often crafted from materials like polyurethane and expanded polystyrene, can be customized to fit various shapes and sizes, providing enhanced protection tailored to specific product needs. For example, a comparative study demonstrated that customized foam packaging solutions result in 30% fewer incidents of product damage compared to standard packaging methods. This level of customization makes foam and honeycomb structures invaluable for industries dealing with sensitive goods, ensuring safe delivery to their destinations.

Utilizing molded pulp and biodegradable materials in cushion packaging offers a dual advantage of protection and sustainability. Molded pulp, made from recycled paper and other natural fibers, provides sufficient protection, ensuring products are secure during shipping. These eco-friendly materials appeal to environmentally conscious consumers and contribute to a positive brand image as more consumers prefer eco-friendly packaging. According to a survey, 72% of consumers are willing to pay more for sustainable packaging, indicating strong market demand. By adopting biodegradable solutions, businesses not only contribute to environmental conservation but also align with consumer preferences, fostering brand loyalty and enhancing their market appeal.

Protective air cushion packaging stands out as a superior choice for shock absorption, especially when shipping delicate items like electronics and glass. This technology effectively absorbs shock, ensuring that such fragile items remain safe during transit. According to studies, damage claims for fragile items can decrease by as much as 40% when air cushion packaging is employed as opposed to traditional methods. This significant reduction highlights the effectiveness of air cushions in providing delicate item protection by contouring around products to distribute any impact evenly.

Air cushion packaging not only excels in protecting items but also significantly contributes to reducing environmental impact through its use of recyclable materials. The packaging solutions crafted from eco-friendly components help minimize waste and support a circular economy. Statistics indicate that using recyclable packaging can reduce landfill contributions by nearly 20%. This shift significantly underscores the role of responsible packaging in promoting environmental sustainability, making air cushions appealing to both businesses and environmentally-conscious consumers.

Additionally, air cushion packaging provides noteworthy cost benefits for high-volume shippers. By reducing the weight of shipments, these packaging solutions help lower transportation costs. For businesses, this can translate into considerable savings through reduced returns of damaged goods and fewer demands for shipping credits. Companies leveraging air cushion technology have reported cost savings of up to 30% related to fewer damaged items and optimized shipping efficiency. This cost-efficient design ensures that businesses can maintain product integrity and enhance their bottom line while supporting sustainable practices.

Introducing biodegradable packing list pouches offers a dual advantage: they secure shipping documents and decrease environmental impact. These eco-friendly pouches ensure that critical information such as invoices and packing slips are protected, while their biodegradable nature caters to sustainability goals. Certified by agencies such as ASTM D6866, these pouches are compostable, breaking down naturally without leaving harmful residues. By integrating biodegradable materials into standard shipping processes, businesses can effectively reduce waste and contribute positively to the environment.

Reusable packing slip envelopes streamline packing processes, enhancing efficiency within the supply chain. These durable envelopes are designed to withstand multiple uses, significantly reducing the need for single-use materials. By adopting reusable envelopes, companies can also achieve long-term cost savings through minimized expenditure on packing materials. Furthermore, reducing the usage of disposable envelopes decreases overall waste production, aligning with corporate sustainability initiatives and contributing to a smaller carbon footprint.

Closed-loop systems exemplify a pivotal approach in recycling cushioning materials, integrating used packaging back into production processes. These systems focus on collecting, processing, and reusing materials like air pillows and foam inserts, effectively creating a circular economy. Companies such as Sealed Air Corporation have successfully implemented these systems, exemplifying reduced waste and resource optimization. By embracing closed-loop systems, businesses not only conserve raw materials but also enhance sustainability credentials, aligning with modern environmental goals.

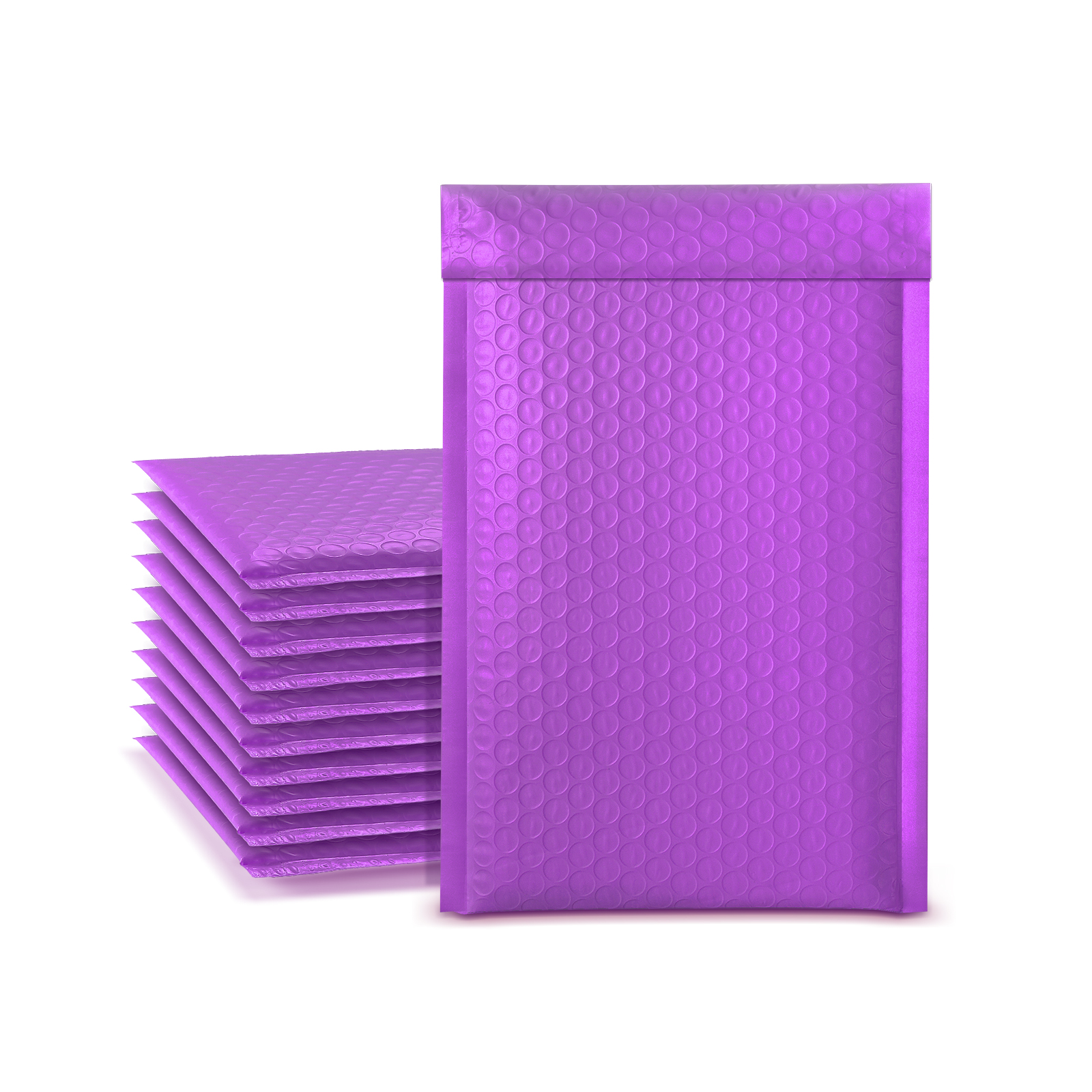

Using both primary and secondary protective layers is crucial in enhancing the protection of fragile items during shipment. Primary packaging typically involves directly enclosing the product to shield it from direct physical damage and environmental factors. Examples include materials like bubble wrap or foam inserts that provide initial cushioning. Secondary protective layers add an extra defensive layer, often involving corrugated boxes or padded mailers that offer additional impact absorption. By combining these layers, businesses can create optimal cushioning solutions that minimize the risk of damage throughout the supply chain journey.

3D-printed packaging introduces a revolutionary approach to creating custom-fit solutions tailored to specific products. This technology allows for the production of packaging that conforms precisely to the dimensions and contours of an item, reducing material waste and ensuring a snug, secure fit. The precision of 3D printing not only improves the protection of fragile items but also enhances the sustainability of the packaging process by minimizing excess material usage. Additionally, the efficiency gained from such customized solutions can streamline logistics, making operations more cost-effective and environmentally friendly.

Smart packaging sensors are emerging as vital tools in the realm of damage monitoring during transit. These sensors track various conditions such as temperature, humidity, and impact, offering real-time data that can inform businesses about potential risks to their shipments. By utilizing this information, companies can implement proactive measures to mitigate damage, thus optimizing shipping practices. This data-driven approach not only enhances the reliability of fragile shipments but also provides valuable insights that can be used to continuously refine and improve packaging and transportation strategies.